Injection Molding Part Design Services from Leading China Manufacturer

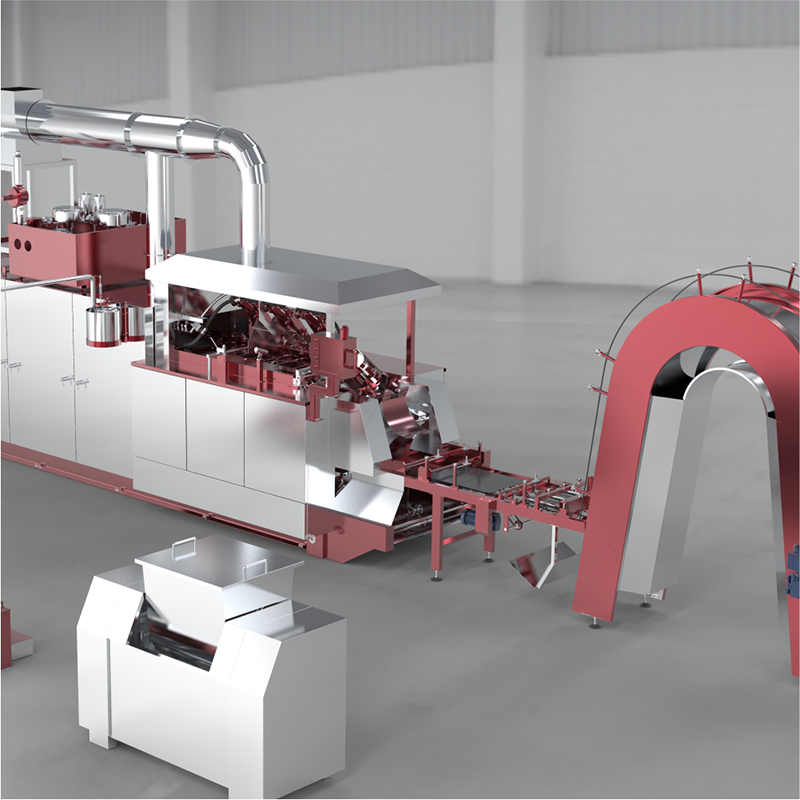

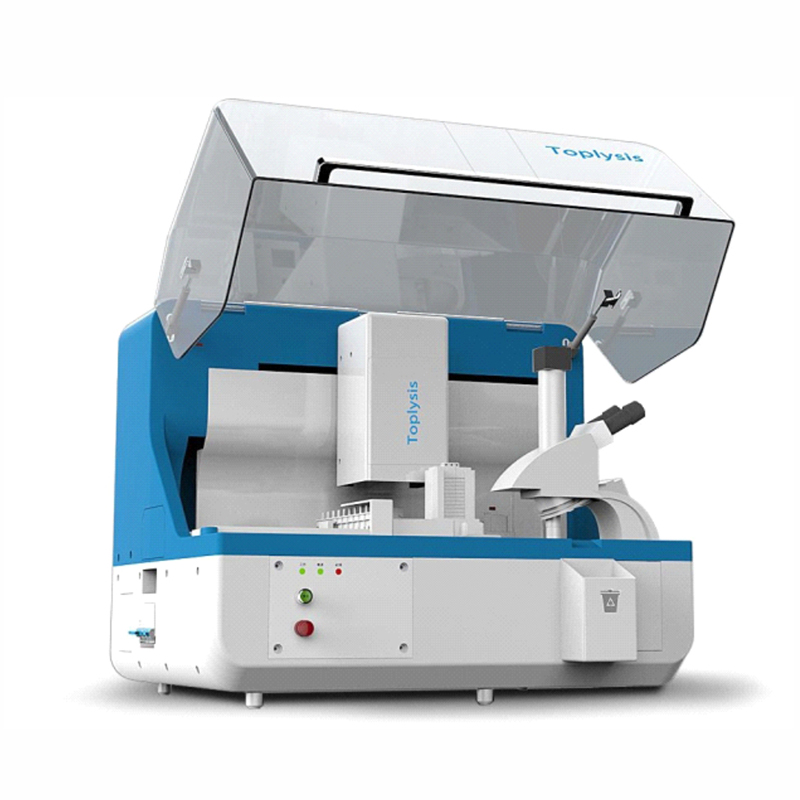

When it comes to Injection Molding Part Design, I understand the critical need for precision and efficiency. As a manufacturer based in China, we specialize in creating high-quality designs that meet diverse industry requirements. Our team works closely with you to ensure every detail aligns with your specifications and operational goals. I know that choosing the right partner can be overwhelming, but our expertise in both design and manufacturing means you can trust us to deliver reliable, cost-effective solutions. We leverage advanced technologies and materials, focusing on durability and sustainability. Whether you need prototypes or scale production, we prioritize your needs and timelines. Let’s collaborate to bring your ideas to life, ensuring each part not only functions perfectly but also enhances your product's overall performance. Together, we can achieve the results you've been looking for in Injection Molding Part Design.

Injection Molding Part Design Factory Is The Best

When it comes to injection molding part design, selecting the right factory can significantly impact both the quality of your products and your bottom line. A top-tier injection molding part design factory offers a range of benefits, ensuring that your components are produced with precision, efficiency, and innovation. These factories leverage advanced technology and experienced engineers to create intricate designs that meet the specific demands of various industries. The focus on high-quality materials and state-of-the-art machinery allows for the production of durable and reliable parts that can withstand rigorous use. Moreover, the best factories prioritize customer collaboration, enabling you to share your vision and requirements openly. This partnership approach ensures that the final products not only fulfill technical specifications but also align with market trends and consumer expectations. Additionally, the integration of sustainable practices and eco-friendly materials into the manufacturing process reflects a commitment to both quality and environmental responsibility, making your products more appealing in today's competitive landscape. In summary, choosing a reputable injection molding part design factory is essential for any global buyer seeking high-quality, customized solutions. By partnering with an experienced team that values precision, collaboration, and sustainability, you can enhance your product offerings and achieve greater success in the marketplace. Investing in this vital aspect of your supply chain is a step toward ensuring the longevity and competitiveness of your business.

Injection Molding Part Design Factory Is The Best

| Part Name | Material | Weight (grams) | Dimensions (mm) | Cycle Time (seconds) |

|---|---|---|---|---|

| Gear Cover | Polypropylene (PP) | 150 | 120 x 80 x 30 | 25 |

| Electronic Enclosure | Acrylonitrile Butadiene Styrene (ABS) | 200 | 150 x 100 x 50 | 30 |

| Connector Housing | Polycarbonate (PC) | 75 | 60 x 40 x 20 | 15 |

| Automotive Bracket | Nylon (PA) | 250 | 100 x 70 x 40 | 20 |

| Bottle Cap | Polyethylene (PE) | 30 | 40 x 40 x 10 | 10 |

Related Products