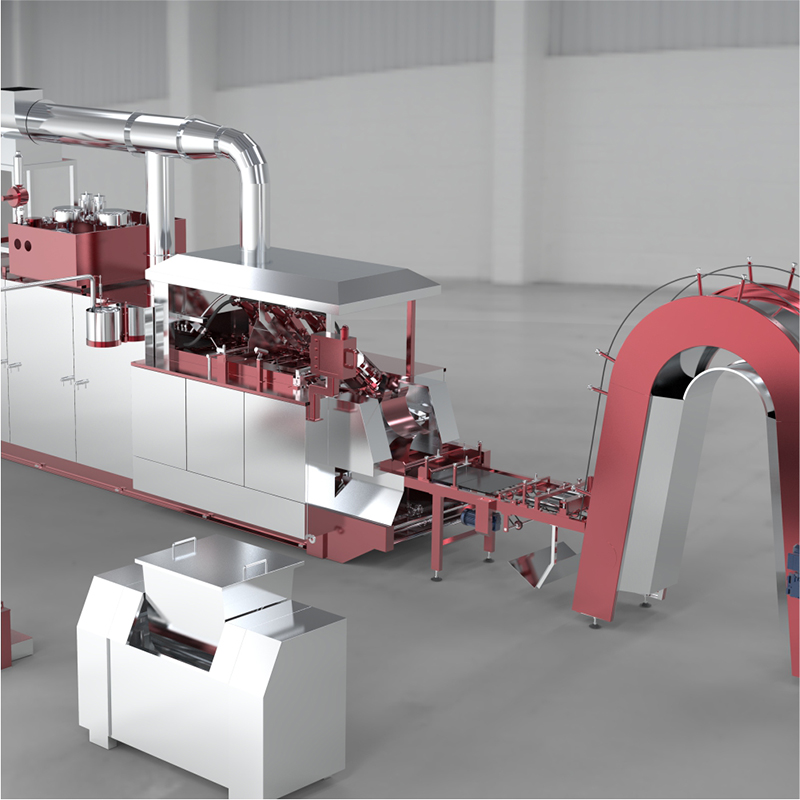

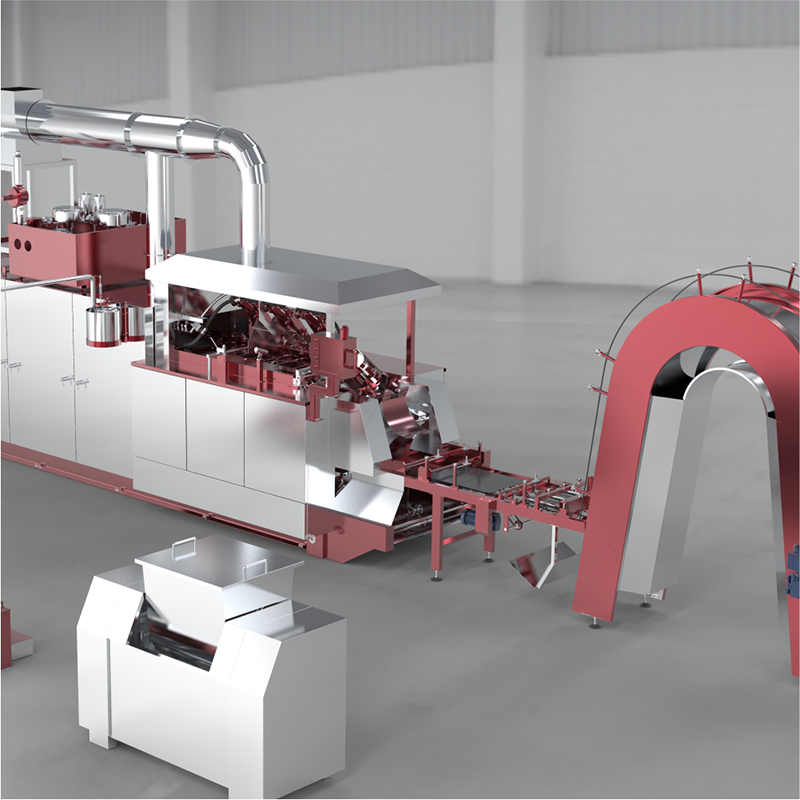

【Ndustrial Design Product Development】 Full Automatic Biscuit Production Line

Product Introduction

The roll printing biscuit forming machine is used for the roll printing of crisp biscuits. It accepts the dough that has been mixed by the flour mixing machine, and the biscuits of various shapes formed by the roll printing are spoiled. The machine is simple in structure. The separating knife is equipped with an adjustable device, which can be adjusted to the best position. The roller printing roller is specially designed to overcome the uneven wear of the separating knife. Both sides of the demoulding pressure roll can be adjusted, which has the advantages of easy mold change and high yield. The vertical roll printing machine can be assembled on the roll cutting machine without affecting the normal production of the roll cutting machine.

Product Display

The oil injector is used for evenly spraying oil on the surface of green biscuit after the biscuit is peeled and formed. Other edible pastes can improve the surface quality of biscuits, improve the taste of biscuits, and increase the variety of designs. The machine adopts imported advanced frequency converter for stepless speed regulation, with stable speed and good energy saving. The whole machine is mainly made of stainless steel, which conforms to food hygiene. It is an ideal auxiliary equipment for biscuit production line

The turning machine is used for cooling and conveying biscuits after baking. There are many forms of 90 °, 180 ° and straight line, which are applicable to different plant requirements. It can also be specially designed for users according to their special plant conditions. The machine has electromagnetic speed regulation, which can be adjusted according to the requirements of biscuit baking capacity, convenient and reliable. At the same time, the biscuits shall be arranged in order to facilitate the packing.

Product Advantage

The biscuit finishing machine is a new generation of equipment that can erect the cooled biscuits and closely arrange them into orderly rows, which can effectively improve the working efficiency of biscuit packaging. Advanced frequency converter is used for stepless speed regulation, with stable speed and high efficiency and energy saving; Equipped with magnetic separator, the width can be adjusted quickly. The special structure design is suitable for ultra-thin biscuits and other biscuits with different dimensions.

It is suitable for packaging various regular objects such as moon cakes, rice noodles, snow cakes, egg yolk pies, sarkima, chocolate, candy, bread, instant noodles, biscuits, medicines, daily necessities, industrial parts, cartons or trays.

This production line can be arbitrarily combined according to the site requirements of users and the requirements of biscuit technology to achieve ideal results. The biscuit production line adopts imported electrical components, variable frequency speed regulation, energy saving and reliable, single control and joint control.