Top China Manufacturer for Quality Metal Die Casting Solutions

As a leading manufacturer in China, we specialize in high-quality metal die casting tailored to meet your specific needs. Our advanced manufacturing processes ensure precision and durability, making our products ideal for a wide range of applications, from automotive to industrial machinery. We get it — finding a reliable partner in the metal die casting industry can be tough. That's why we prioritize not just the quality of our castings but also the relationships we build with our clients. With years of experience and a commitment to excellence, our team is always ready to work closely with you, ensuring that every product meets your expectations. Whether you need prototypes or large production runs, we have the capabilities to deliver on time and within budget. Trust us to provide just the right metal die casting solutions that will enhance your operations and drive your business forward. Let’s create something remarkable together!

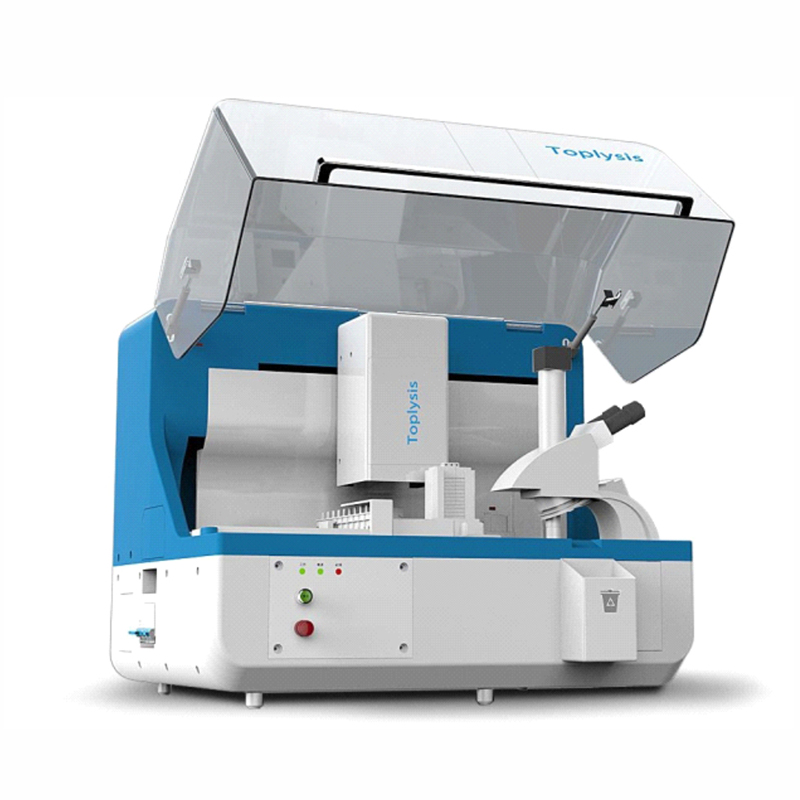

Metal Die Casting Supplier Now Trending

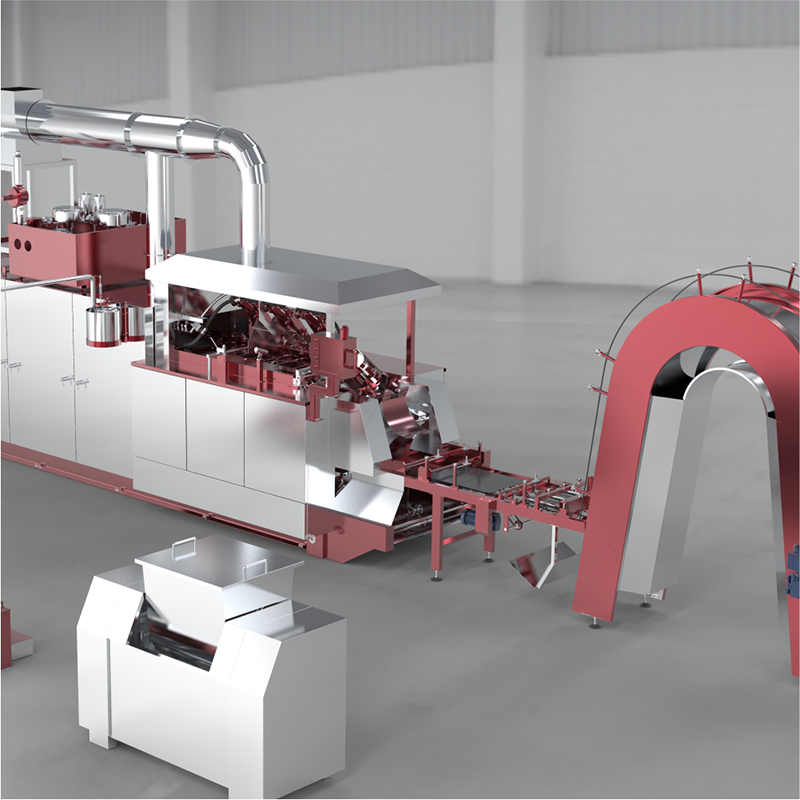

In the ever-evolving landscape of manufacturing, metal die casting has emerged as a pivotal technique for creating high-quality, precision parts. As demand for innovative solutions grows, suppliers specializing in this process are increasingly in the spotlight. This trend is driven by the need for efficiency, cost-effectiveness, and superior product performance across various industries, including automotive, aerospace, electronics, and consumer goods. Choosing the right supplier is paramount for global purchasers aiming to stay competitive. Attributes like advanced technology, expertise in engineering, and a commitment to sustainability play a critical role in selecting the best partner. The current market landscape showcases suppliers who not only offer outstanding die casting services but also emphasize customization to meet specific client requirements. By leveraging cutting-edge technology and materials, these suppliers can provide tailored solutions that enhance product quality and reduce time to market. As manufacturers and businesses look to streamline their production processes, the need for reliable partners in metal die casting is more critical than ever. Engaging with a trusted supplier can pave the way for innovation, helping to navigate the complexities of modern production demands while ensuring that quality and efficiency remain at the forefront of every project. It’s essential for global buyers to stay abreast of the latest trends and advancements in the sector to make informed decisions that drive success.

Metal Die Casting Supplier Now Trending

| Category | Material Type | Production Volume | Lead Time | Application |

|---|---|---|---|---|

| Automotive | Aluminum | 5000 units/month | 2 weeks | Engine Parts |

| Electronics | Zinc | 8000 units/month | 4 weeks | Casings and Housings |

| Industrial | Magnesium | 3000 units/month | 3 weeks | Machinery Parts |

| Consumer Goods | Aluminum | 6000 units/month | 5 weeks | Kitchen Appliances |

| Aerospace | Titanium | 1000 units/month | 6 weeks | Structural Components |

Related Products