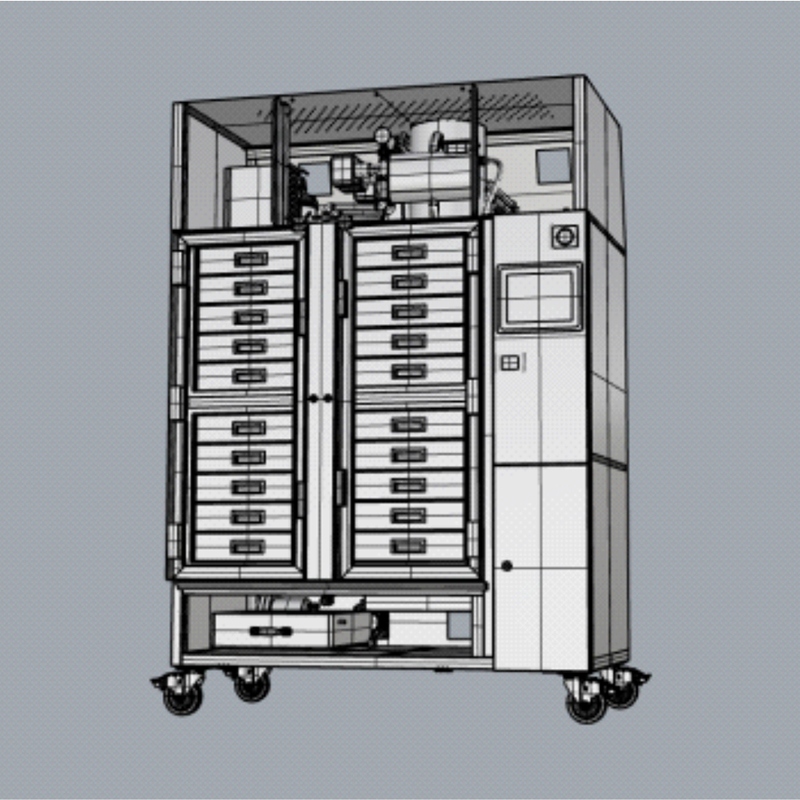

【Ndustrial Design Product Development】 Intelligent interconnection multi-function shared pretreatment kitchen

Product selling points

First, products are purchased by installment to reduce the economic pressure of users.

Second, in terms of food materials, cold-chain distribution - has its own warehouse, specializing in purchasing, storing, cutting and packaging raw materials; Cold chain truck distribution, constant temperature refrigeration and sealed refrigerated room will not be polluted in the whole process.

Third, scan the code to order meals, place orders in advance, and there will be no congestion.

Fourth, screen advertising and Internet dating.

Fifth, it covers a small area and can be placed in the tea room or corner.

Core competitiveness

1、 The equipment is powered by 220V AC mains power, and the whole machine is controlled at full load (18 kW). Single operation capacity (9 kW)

2、 The main board of the controller has the function of detecting the grid voltage, working power of the whole machine, and reporting the fault code in case of abnormality.

3、 The pressure relief link at the end of cooking is to open the pressure relief solenoid valve. The sewage collection bucket collects the sewage after steam separation. The weighing module under the sewage bucket detects the status of the sewage bucket and reports the water volume information in real time. If the sewage pipe is connected, there is no sewage collection process.

4、 During the operation of the whole machine, if the control main board detects the abnormal sensor data, it will immediately stop the operation of each functional module. If the steam generator module has worked, it will open the pressure relief solenoid valve to relieve the pressure and report the fault code.

5、 If the equipment is disconnected in standby state (unable to communicate effectively with the platform), the platform will send an alarm message and the equipment will enter the fault state to prompt that the disconnected equipment will not work except for the normal switch. If there is a disconnection during cooking, the controller completes the cooking operation or pauses the cooking process (select one of the two modes) through the instructions issued by the platform+the preset cooking procedure flow, but the disconnection alarm is also triggered. The device can terminate the cooking process through administrator login.

6、 Safety: the whole machine is equipped with emergency stop button, hardware active pressure relief valve, pressure relief solenoid valve, leakage protector, pressure sensor, temperature sensor, solenoid valve sensor and other detection facilities.

7、 Once the distribution center confirms that the food distribution is completed and enters the fresh-keeping process, the cabinet door is locked (if it needs to be opened, it needs to verify the identity), and once it enters the heating process, the equipment cabinet door is locked (if it needs to be opened, it needs to stop the operation of the whole machine and wait for the completion of pressure relief, the specific verification method is to be determined).

8、 Internally installed active pressure relief valve can actively relieve pressure when the internal pressure is greater than the safety value of the pressure valve. There are two built-in pressure sensors, and the pressure sensor data is read and monitored by the control board in real time. When it is greater than the set safety value, the alarm information will be sent to the platform, and the pressure relief solenoid valve will be triggered to release the pressure and upload the equipment fault information after the cooking process.