Top China Manufacturer for Expert Bridge Pier Design Solutions

Are you in need of reliable bridge pier design solutions? As a manufacturer based in China, we understand the critical role that sturdy and efficient designs play in infrastructure projects. Our bridge pier designs are crafted with precision, ensuring both durability and compliance with industry standards. I’ve seen firsthand how our innovative approaches can meet the unique requirements of various projects, providing solid support for bridges of all sizes. We prioritize quality, using state-of-the-art materials and technologies that enhance performance and longevity. Whether you’re a contractor or an engineer, our team is ready to collaborate closely with you to tailor solutions that align with your specific needs. Trusting our expertise means investing in the safety and reliability of your infrastructure. Let’s work together to elevate your projects with our superior bridge pier designs from China, where quality meets expertise.

Bridge Pier Design Application Where Innovation Meets 2025

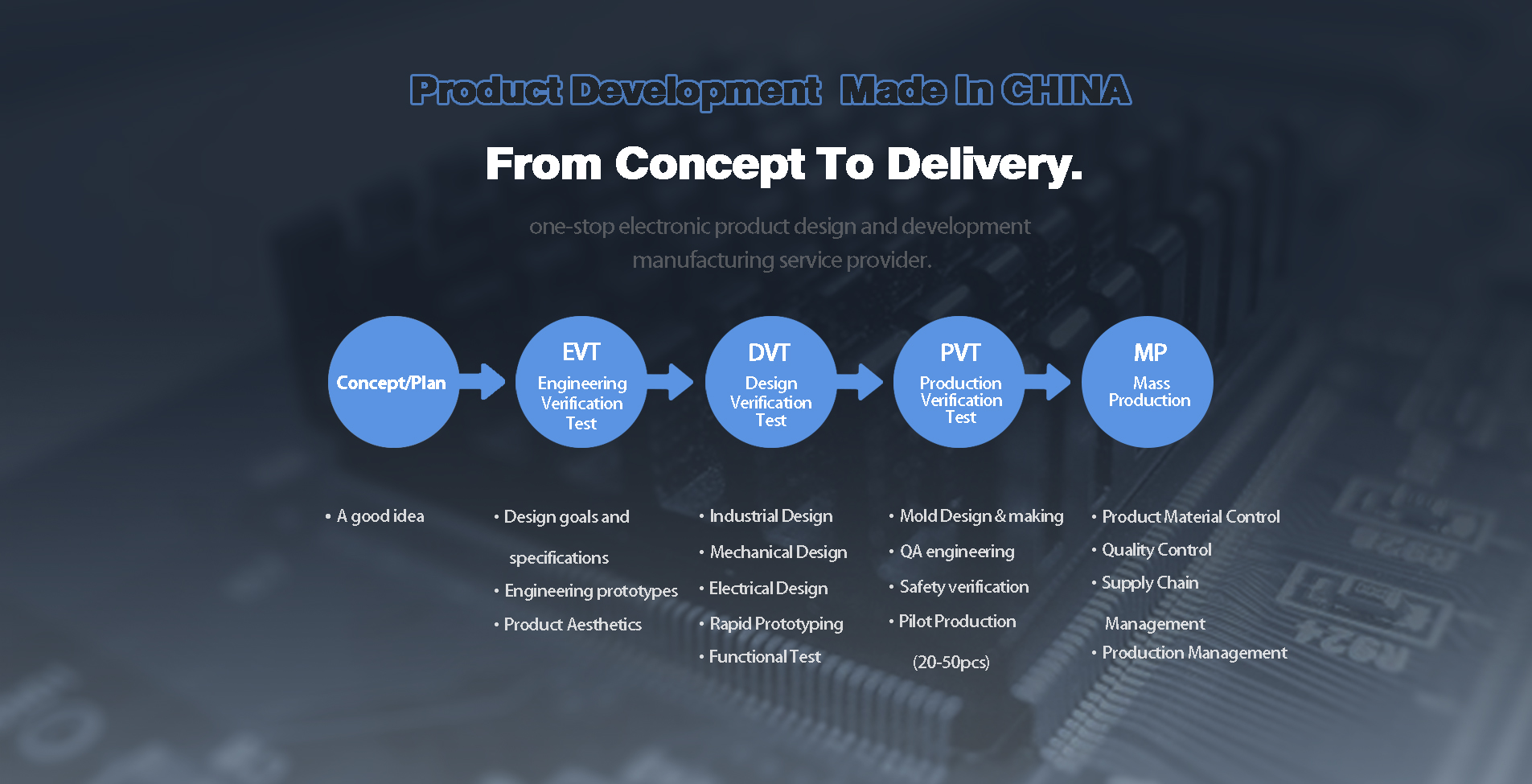

In an era where infrastructure demands are rapidly evolving, the design and construction of bridge piers have emerged as critical elements in ensuring safety, durability, and sustainability. The application of advanced materials and innovative design techniques in bridge pier construction not only enhances structural integrity but also significantly reduces long-term maintenance costs. As we approach 2025, the integration of technology in engineering practices becomes more essential than ever, paving the way for smarter, more resilient transportation networks. Innovative design solutions are at the forefront of meeting the challenges posed by modern engineering projects. Utilizing cutting-edge computer modeling and simulation tools allows engineers to optimize bridge pier designs for various environmental conditions and loading scenarios. These advancements not only improve performance but also facilitate the use of eco-friendly materials and construction methods. As global procurement professionals, understanding these trends is crucial for making informed decisions that prioritize efficiency and sustainability in infrastructure development. Collaboration among stakeholders—engineers, builders, and material suppliers—will be key to driving innovation in bridge pier design. By fostering partnerships that encourage knowledge sharing and technological advancements, the industry can ensure that infrastructure projects meet the highest standards of safety and reliability while also being economically viable. As we look toward 2025, it is imperative for decision-makers to embrace these innovative solutions, positioning themselves as leaders in the rapidly evolving landscape of civil engineering.

Bridge Pier Design Application Where Innovation Meets 2025

| Design Element | Material | Load Capacity (kN) | Construction Year | Innovative Feature |

|---|---|---|---|---|

| Pier Type A | Reinforced Concrete | 500 | 2025 | Self-Cleaning Surface |

| Pier Type B | Steel | 800 | 2024 | Modular Design |

| Pier Type C | Composite Material | 650 | 2026 | Eco-Friendly Components |

| Pier Type D | Prestressed Concrete | 700 | 2023 | Seismic Resilience |

Related Products