Die Casting Mold Design: Top China Manufacturer Solutions for Quality Molds

When it comes to die casting mold design, I understand the significance of precision and durability in every project. As a manufacturer based in China, I take pride in my ability to create molds that meet the diverse needs of clients across various industries. Our designs are tailored to provide optimal performance and efficiency, ensuring that every component produced is of the highest quality. I focus on utilizing advanced techniques and technology to enhance mold life and reduce production costs, which is crucial for your business's bottom line. My dedication to innovation and attention to detail means that I can help you streamline your manufacturing process, ultimately driving better results. Partnering with us not only gives you access to top-notch die casting mold design but also a reliable collaborator committed to your success. Let’s work together to bring your vision to life with molds that exceed your expectations!

Die Casting Mold Design Pioneers in the Field Manufacturers You Can Rely On

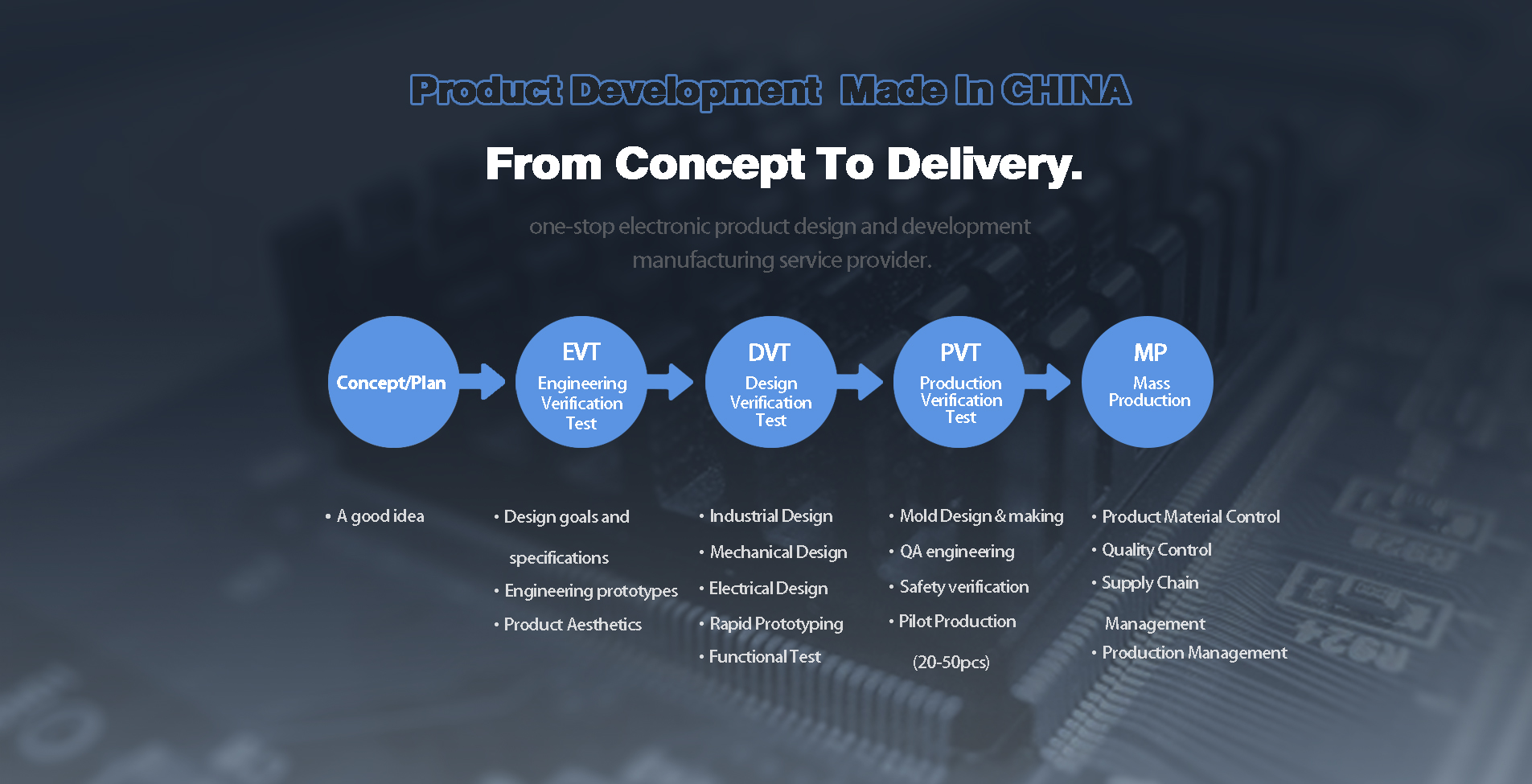

In the realm of die casting mold design, innovation and reliability are two critical factors that global buyers seek. The advancement in technology and materials has revolutionized the manufacturing landscape, enabling producers to create intricate and high-precision molds that cater to diverse industries. These mold design pioneers prioritize efficiency and quality, ensuring that their solutions not only meet but exceed the expectations of buyers worldwide. By leveraging cutting-edge techniques and deep industry knowledge, they offer customized mold designs that optimize production processes, reduce waste, and enhance product performance. Moreover, global buyers value partnerships with manufacturers who understand the importance of timely delivery and cost-effectiveness. A strong collaboration between companies fosters an environment of transparency and continuous improvement, enabling them to respond swiftly to market demands and changing client needs. As the industry evolves, ongoing communication and support become essential, ensuring that buyers can confidently navigate their projects from conception to final production. Ultimately, choosing the right manufacturing partner in die casting mold design can make a significant difference for businesses looking to improve their bottom line. By relying on these industry pioneers, companies can streamline their operations, achieve unparalleled quality, and, most importantly, meet their customers' diverse needs while staying competitive in an ever-changing market.

Die Casting Mold Design Pioneers in the Field Manufacturers You Can Rely On

| Manufacturer Type | Experience (Years) | Specialization | Quality Certifications | Production Capacity (Units/Month) |

|---|---|---|---|---|

| Custom Die Casting | 15 | Automotive Parts | ISO 9001, IATF 16949 | 50,000 |

| Aluminum Die Casting | 20 | Consumer Electronics | ISO 9001 | 30,000 |

| Zinc Die Casting | 10 | Home Appliances | ISO 9001, RoHS | 40,000 |

| Magnesium Die Casting | 12 | Telecommunications Equipment | ISO 9001 | 25,000 |

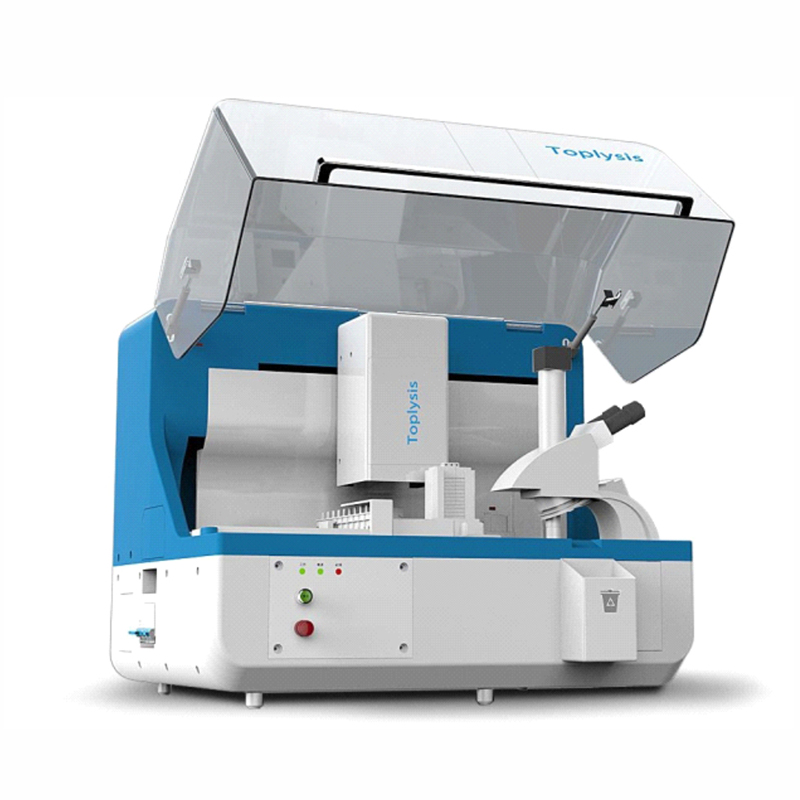

Related Products