Top China Manufacturer for Electronics Enclosure Design Solutions

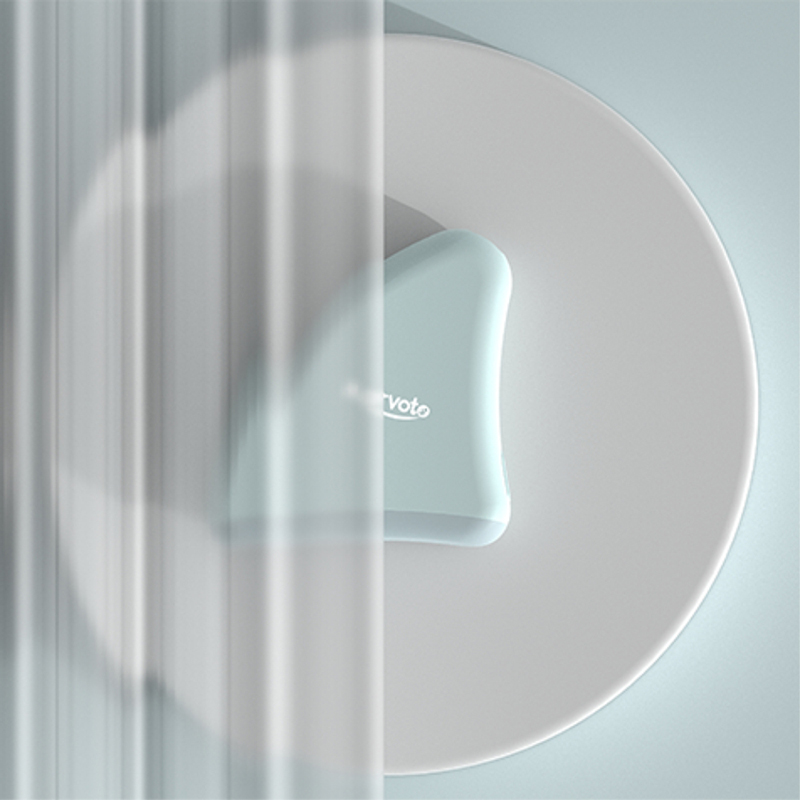

When it comes to electronics enclosure design, I understand the challenges you face. Working with a reliable manufacturer in China means you can expect high-quality products tailored to your specifications. My experience has taught me that the right enclosure not only protects your valuable electronic components but also enhances their performance. I prioritize your needs, ensuring that every design is both functional and aesthetically pleasing. With a wide variety of materials and custom options, you have the flexibility to choose an enclosure that integrates perfectly into your product line. My commitment to quality means you won't just get a product, you'll get a solution designed to last. Let’s collaborate to create the perfect enclosure that meets your demands and elevates your business. Together, we can turn your ideas into reality while ensuring durability and efficiency in every project. Your satisfaction is important, and I’m here to support you every step of the way.

Electronics Enclosure Design Stands Out Now Trending

In today's fast-evolving electronic landscape, the importance of effective electronics enclosure design cannot be overstated. As industries strive for innovation while ensuring safety and functionality, manufacturers are embracing trends that enhance both aesthetic appeal and performance. Advanced materials such as lightweight aluminum and robust plastics are increasingly being utilized to create enclosures that not only protect sensitive components but also adapt to varying environmental conditions. This trend is particularly vital for sectors like telecommunications, medical devices, and industrial machinery, where reliability is paramount. Recent advancements in design technology, including 3D modeling and simulation software, have facilitated the development of more intricate and efficient enclosure designs. These innovations enable engineers to foresee potential issues, optimize airflow, and enhance thermal management, all of which are crucial for sustaining the performance of electronic systems. Furthermore, customizable options are more in demand than ever, allowing businesses to tailor enclosures to specific applications, thus driving efficiency and enhancing overall product value. As we look to the future, the integration of sustainable practices within electronics enclosure design is becoming a defining trend. Companies are increasingly prioritizing eco-friendly materials and recyclable designs, reflecting a growing commitment to environmental responsibility. This shift not only meets regulatory demands but also resonates with consumers who are more conscious of their ecological footprint. Embracing these trends is essential for businesses aiming to stay competitive in a global marketplace, ensuring they meet the expectations of both clients and end-users while contributing positively to the planet.

Electronics Enclosure Design Stands Out Now Trending

| Design Type | Material | Applications | Trends | Sustainability |

|---|---|---|---|---|

| Modular Enclosure | Aluminum | Telecommunications | Customizable Designs | Recyclable Materials |

| NEMA Enclosure | Stainless Steel | Industrial Equipment | Weatherproofing Features | Eco-Friendly Coatings |

| Custom Rack | Plastic | Data Centers | Space Optimization | Energy-efficient Designs |

| Thermal Management Enclosure | Steel | Power Supply Units | Heat Dissipation Technology | Sustainable Sourcing |

| IP Rated Enclosure | Composite | Outdoor Equipment | Ingress Protection | Low-Carbon Materials |

Related Products