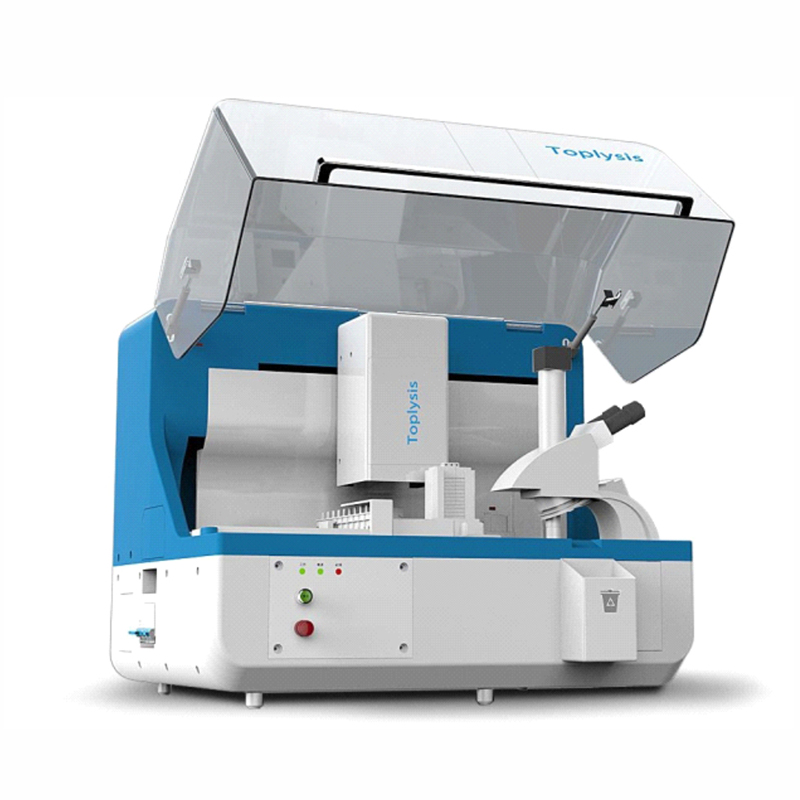

Top China Manufacturer for Gate Injection Molding Solutions

When it comes to gate injection molding, I understand the importance of quality and efficiency for your manufacturing needs. As a leading manufacturer in China, we pride ourselves on delivering precision-engineered solutions that enhance your production line. With our advanced technology and skilled team, we ensure that each component meets the highest industry standards, allowing you to maintain a competitive edge in your market. Our process is flexible and tailored according to your specifications, whether you need small or large volumes. I believe in open communication and collaboration, ensuring that your expectations are not just met but exceeded. Choosing us means you’re partnering with a dedicated manufacturer that values your business and aims to provide long-lasting solutions. Let’s work together to optimize your production and bring your projects to life efficiently and affordably.

Gate Injection Molding Stands Out Leads the Global Market

In today's competitive manufacturing landscape, gate injection molding is increasingly recognized for its unique advantages, positioning it as a frontrunner in the global market. This technique not only enhances efficiency but also optimizes the precision of molded components. With the ability to accommodate complex designs and reduce production waste, gate injection molding provides a sustainable solution that meets the demands of various industries, from automotive to consumer goods. The key to its success lies in the strategic design of the gating system, which ensures a smooth flow of materials, minimizing defects and ensuring superior quality. This results in faster cycle times and cost savings, making it an attractive option for global procurement professionals. As companies continue to prioritize innovation and efficiency, they are turning to gate injection molding as a reliable choice for scalable production. Moreover, with advancements in technology, the capabilities of gate injection molding are expanding, allowing manufacturers to experiment with various materials and configurations. This flexibility not only caters to the diverse needs of clients but also opens new avenues for product development. By embracing this innovative molding technique, companies can lead the charge in maintaining competitiveness and meeting evolving market demands.

Gate Injection Molding Stands Out Leads the Global Market

| Region | Market Share (%) | Growth Rate (2021-2026) (%) | Material Type | Application |

|---|---|---|---|---|

| North America | 30 | 5.2 | Polypropylene | Automotive |

| Europe | 25 | 4.8 | Polystyrene | Consumer Goods |

| Asia-Pacific | 35 | 6.1 | Polycarbonate | Electronics |

| Latin America | 5 | 3.5 | PVC | Medical Devices |

| Middle East & Africa | 5 | 3.2 | ABS | Construction |

Related Products