Compression Mold Design by Leading Manufacturers in China

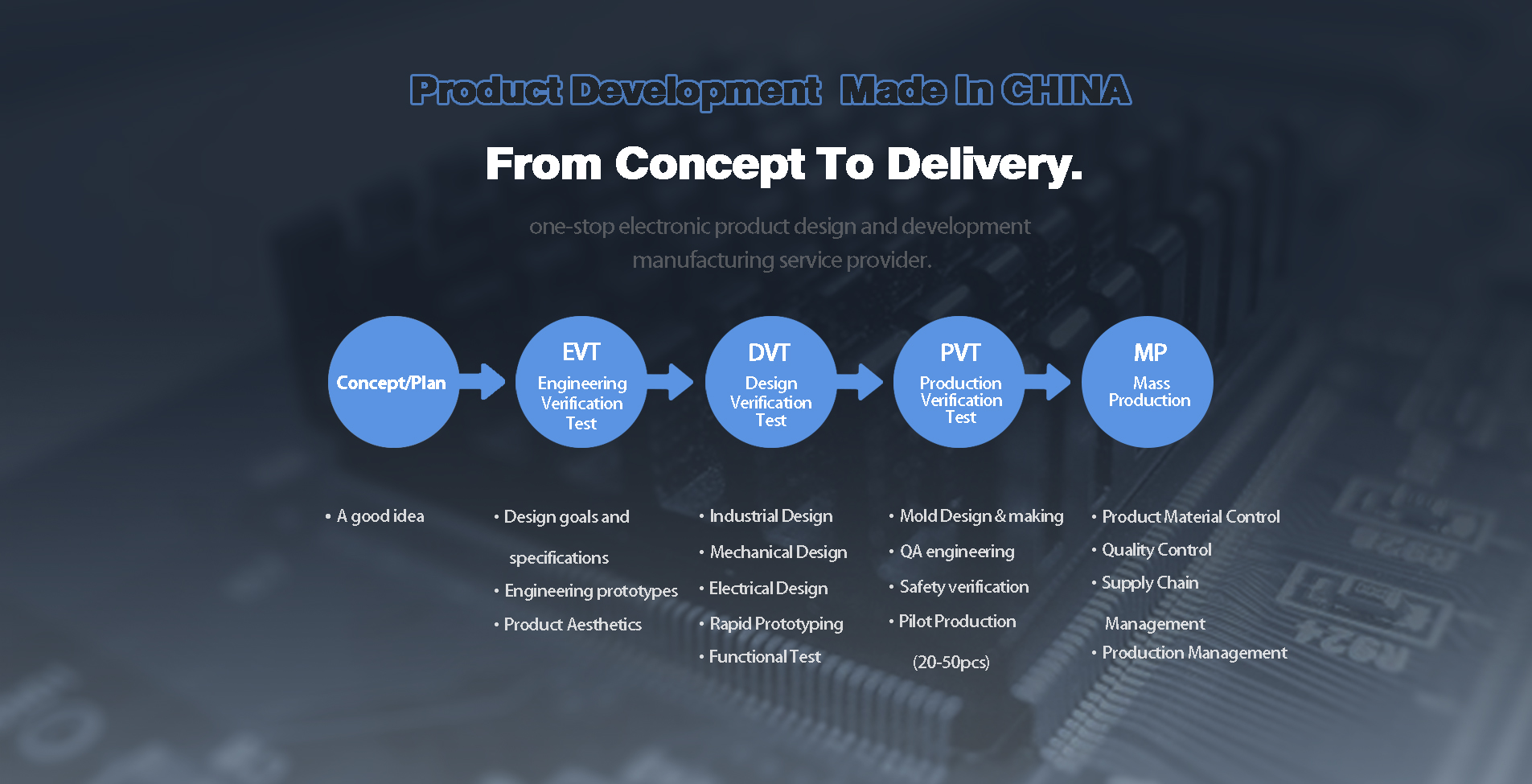

When it comes to Compression Mold Design, I understand the importance of quality and precision in the manufacturing process. As a manufacturer based in China, I prioritize delivering molds that meet the highest standards. My designs are tailored to enhance efficiency and reduce production times, ensuring that your projects stay on track and within budget. I pride myself on my attention to detail and commitment to innovation, providing solutions that cater to your specific needs. Whether you're producing intricate components or large-scale parts, I can offer a range of customizable options. My extensive experience in this field allows me to anticipate challenges and deliver reliable outcomes. With competitive pricing and streamlined communication, I strive to be your go-to partner in Compression Mold Design. Let's work together to create exceptional products that exceed your expectations and drive your business forward. Don't hesitate to reach out—I’m here to help you make the right choice!

Compression Mold Design Dominates Where Service Meets Innovation

Compression mold design plays a pivotal role in the manufacturing landscape, seamlessly blending service with innovation to create superior products. In an era where efficiency and precision are paramount, effective mold design is crucial for industries ranging from automotive to consumer goods. A meticulously crafted compression mold not only enhances production speed but also ensures consistency and quality in the final output. By prioritizing innovation, businesses can leverage the latest technologies, such as advanced simulation software and 3D printing, to optimize mold designs, reduce lead times, and minimize material waste. As global competition intensifies, the ability to offer customized solutions that meet diverse market needs is more critical than ever. Strategic partnerships with experienced suppliers can further streamline the design and manufacturing processes. By harnessing insights from industry experts, companies can adopt best practices in compression mold design, ultimately driving operational excellence. Embracing these advancements not only positions businesses as leaders within their sectors but also elevates customer satisfaction through timely delivery of high-quality products. In conclusion, the intersection of service and innovation in compression mold design presents an exciting opportunity for businesses aiming to excel in today’s dynamic marketplace. By investing in cutting-edge technologies and fostering collaborations, manufacturers can unlock new levels of efficiency and creativity. This strategic approach not only supports current operational goals but also lays a strong foundation for future growth and adaptability in the ever-evolving global economy.

Compression Mold Design Dominates Where Service Meets Innovation

| Dimension | Material Type | Process Type | Lead Time (Days) | Sustainability Rating |

|---|---|---|---|---|

| 120mm x 80mm x 40mm | Aluminum | Injection Molding | 15 | B |

| 150mm x 100mm x 50mm | Steel | Compression Molding | 20 | A |

| 100mm x 70mm x 30mm | Plastic | Thermoforming | 10 | C |

| 200mm x 150mm x 60mm | Composite | Resin Transfer Molding | 25 | A+ |

| 90mm x 60mm x 25mm | Titanium | Metal Injection Molding | 30 | B+ |

Related Products

【Ndustrial Design Product Development】 Intelligent multi-function automatic induction trash can

Read More