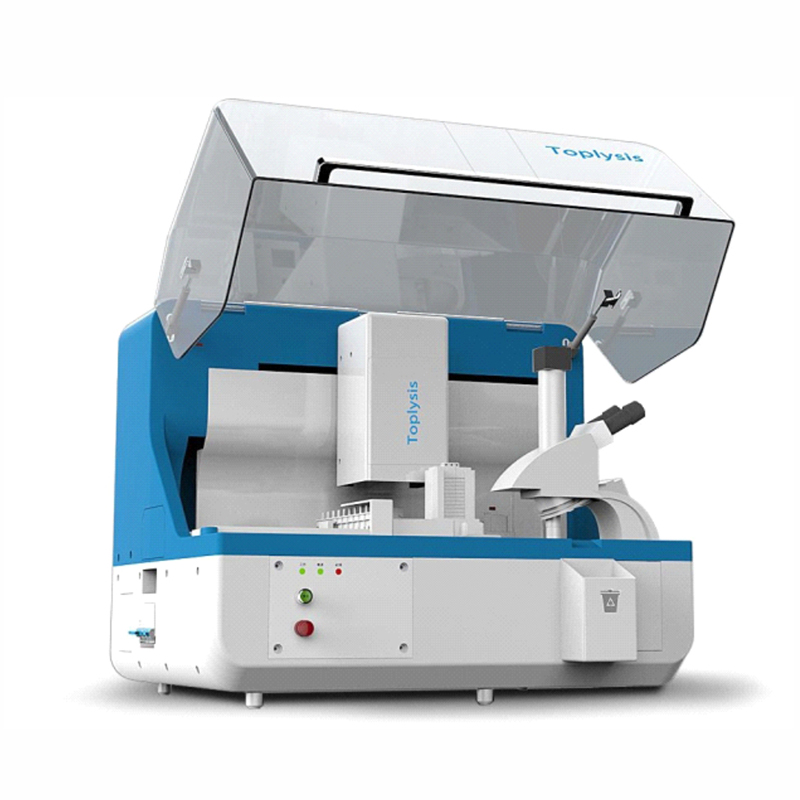

Injection Molding Mold Design by Leading Manufacturer in China

As a professional in Injection Molding Mold Design, I understand the importance of precision and efficiency in every project. Based in China, I have partnered with leading manufacturers who share a commitment to quality. Our molds are meticulously crafted to meet your specific needs, whether you require prototypes or large-scale production runs. With years of experience, I ensure that each design process is seamless, focusing on innovation and cost-effectiveness. Collaborating with our team means you’ll benefit from cutting-edge technology and materials, reducing lead times while maintaining high standards. By choosing us, you’re not just getting a product; you’re getting a partnership aimed at your success. I'm here to support you through every step, ensuring your project is completed on time and within budget. Let's talk about how our Injection Molding Mold Design services can elevate your manufacturing capabilities.

Injection Molding Mold Design Market Leader Winning in 2025

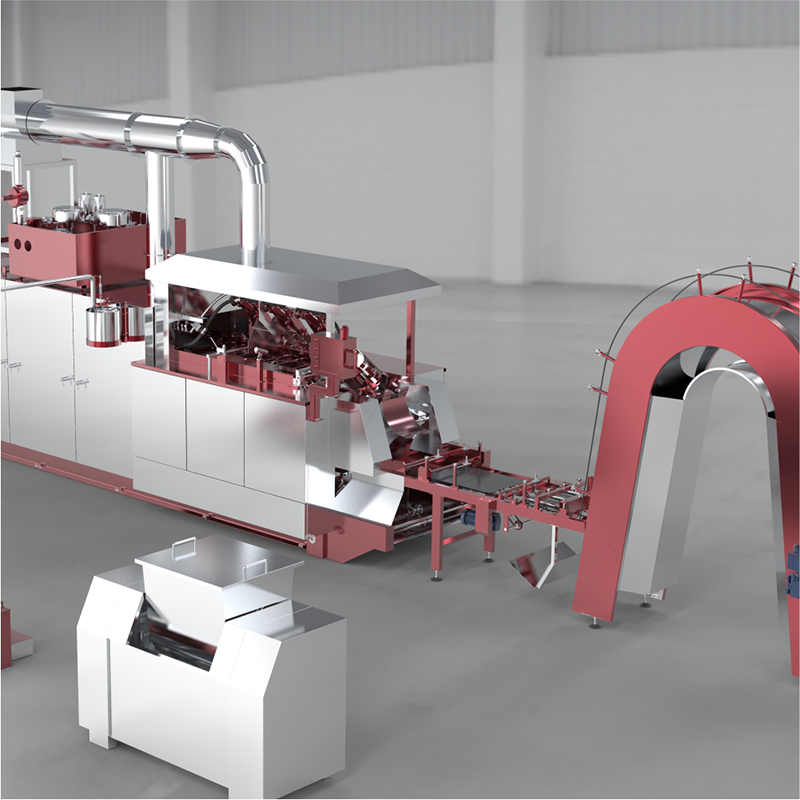

As the injection molding industry continues to evolve, 2025 is set to be a pivotal year for companies seeking innovative solutions and reliable partnerships. The demand for high-quality molded products is surging across various sectors, including automotive, consumer goods, and healthcare. To thrive in this competitive landscape, global buyers must align with leaders who not only understand the intricacies of mold design but also prioritize efficiency, sustainability, and adaptability in their processes. The advancements in technology, particularly in areas such as computer-aided design (CAD) and simulation software, have revolutionized the way molds are developed. By leveraging these tools, businesses can reduce lead times, enhance accuracy, and minimize production costs, ultimately delivering superior products to their customers. As we approach 2025, it becomes imperative for procurement professionals to invest in partnerships that offer cutting-edge mold design solutions tailored to their specific needs, ensuring they stay ahead in a rapidly changing market. Moreover, the focus on sustainability is becoming increasingly vital. Leaders in injection molding are now integrating eco-friendly materials and practices into their operations, responding to the growing demand from consumers and regulations for more responsible manufacturing processes. By aligning with suppliers committed to sustainable practices, businesses can not only improve their market positioning but also contribute positively to the environment. As we look toward the future, the synergy between innovative design, operational efficiency, and sustainability will be key to success in the injection molding mold design market.

Injection Molding Mold Design Market Leader Winning in 2025

| Region | Market Share (%) | Growth Rate (CAGR %) | Key Trends | Challenges |

|---|---|---|---|---|

| North America | 35 | 4.2 | Sustainability, Automation | High Competition |

| Europe | 30 | 3.8 | Innovation in Materials | Regulatory Challenges |

| Asia Pacific | 25 | 5.0 | Rapid Industrialization | Infrastructure Issues |

| Latin America | 5 | 3.2 | Emerging Markets | Economic Instability |

| Middle East & Africa | 5 | 3.5 | Investment in Manufacturing | Political Turmoil |

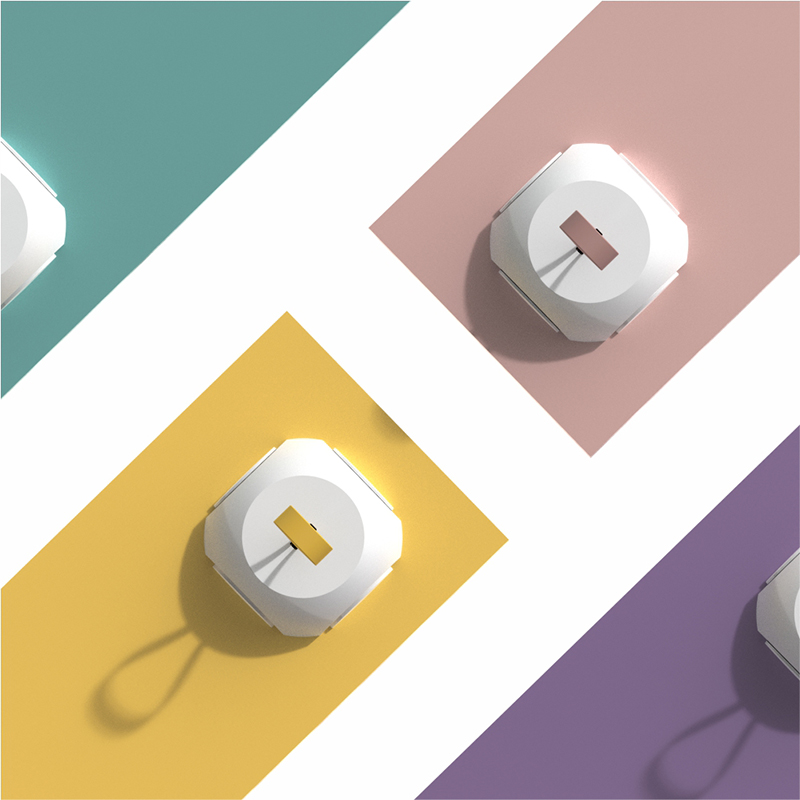

Related Products