China Manufacturer Insights on the System Development Cycle Process

In my experience navigating the complexities of the System Development Cycle, I’ve learned how crucial it is for B2B manufacturers in China to streamline their processes. I understand the unique challenges faced by companies looking to enhance their operational efficiency and product quality. Each phase of the cycle is essential, from planning and design to implementation and maintenance. What sets me apart is my focus on tailored solutions that fit the specific needs of manufacturers. I know that collaboration and clear communication are key to success. By aligning our development stages with your goals, we can achieve a smoother workflow and faster time to market. If you’re seeking a partner who understands the intricacies of the System Development Cycle and the priorities of Chinese manufacturers, I’m here to help you reach new heights in your projects. Let’s elevate your production process together!

System Development Cycle Ahead of the Curve Factory-Direct Excellence

In today's fast-paced global market, staying ahead of the curve is essential for any business aiming to thrive in the competitive landscape. The system development cycle plays a crucial role in ensuring that products are not only innovative but also meet the evolving needs of consumers. Emphasizing factory-direct excellence, our approach integrates every phase of the development cycle— from ideation to production— seamlessly, allowing for maximum efficiency and quality control. By implementing cutting-edge technologies and methodologies, we optimize processes that allow for rapid turnarounds and tailored solutions for our clients. This not only reduces lead times but also lowers costs, providing global buyers with unparalleled value. Our commitment to excellence extends beyond just delivering products; we foster strong partnerships built on trust and transparency, ensuring that our clients are empowered with the insights and support they need for successful procurement. As businesses navigate the complexities of sourcing quality products, understanding the intricacies of the system development cycle can lead to smarter purchasing decisions. Our expertise ensures that we are not just meeting current market demands, but anticipating future trends, enabling our partners to stay competitive and responsive in their respective industries. Embrace the future of procurement with a focus on innovative solutions and factory-direct excellence.

System Development Cycle Ahead of the Curve Factory-Direct Excellence

| Phase | Description | Key Activities | Duration (Weeks) | Stakeholders Involved |

|---|---|---|---|---|

| Planning | Define project scope and objectives. | Requirement gathering, feasibility study. | 2 | Project Managers, Stakeholders |

| Design | Create system architecture and design specifications. | Wireframes, prototypes, design document. | 3 | Design Team, Developers |

| Development | Build the system according to specifications. | Coding, unit testing, integration. | 6 | Developers, QA Team |

| Testing | Evaluate the system for defects and issues. | System testing, user acceptance testing. | 4 | QA Team, End Users |

| Deployment | Release the system to the production environment. | Production setup, data migration. | 2 | IT Team, Users |

| Maintenance | Monitor and update the system as needed. | Bug fixes, enhancements, user support. | Ongoing | Support Team, Users |

Related Products

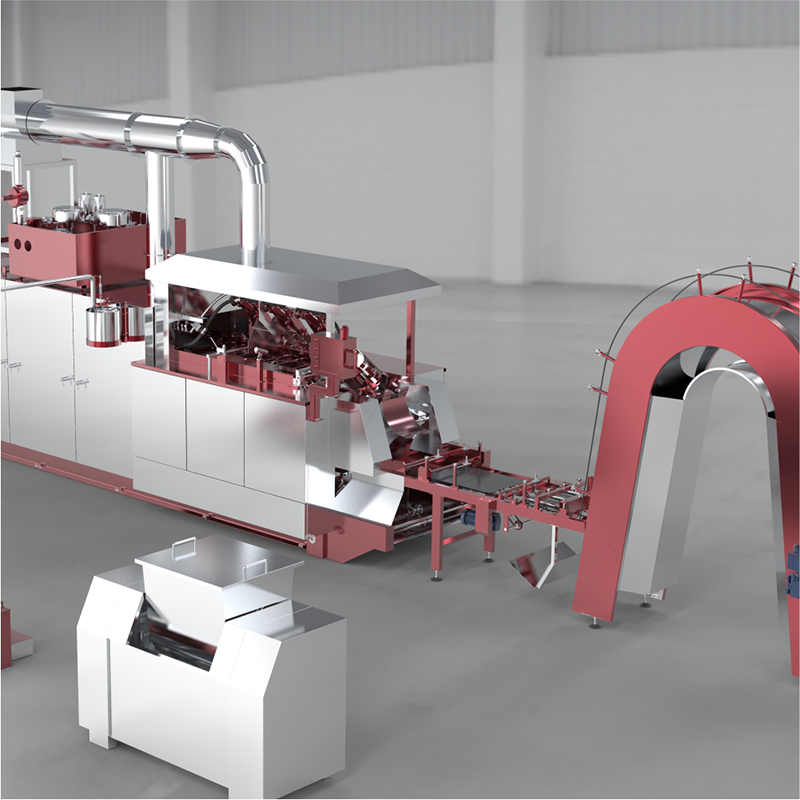

【Ndustrial Design Product Development】 New vehicle radio frequency identification equipment

Read More