Top China Manufacturer for Design of Welded Structures - Quality Solutions

When it comes to the design of welded structures, I understand how crucial it is to find a reliable partner. As a manufacturer based in China, we specialize in delivering top-notch welded solutions tailored to your unique needs. My experience in this field allows me to offer a range of designs that not only meet industry standards but also provide exceptional durability and strength. Whether you need custom structures or standard designs, I’m here to help streamline the process from concept to completion. My commitment to quality assurance means that every project is handled with the utmost care, ensuring that your specifications are met without compromise. Choosing us means accessing advanced welding technologies and skilled craftsmanship, all while maintaining competitive pricing. Let’s work together to bring your welded structure visions to life; reaching out is the first step towards a successful partnership and outstanding results!

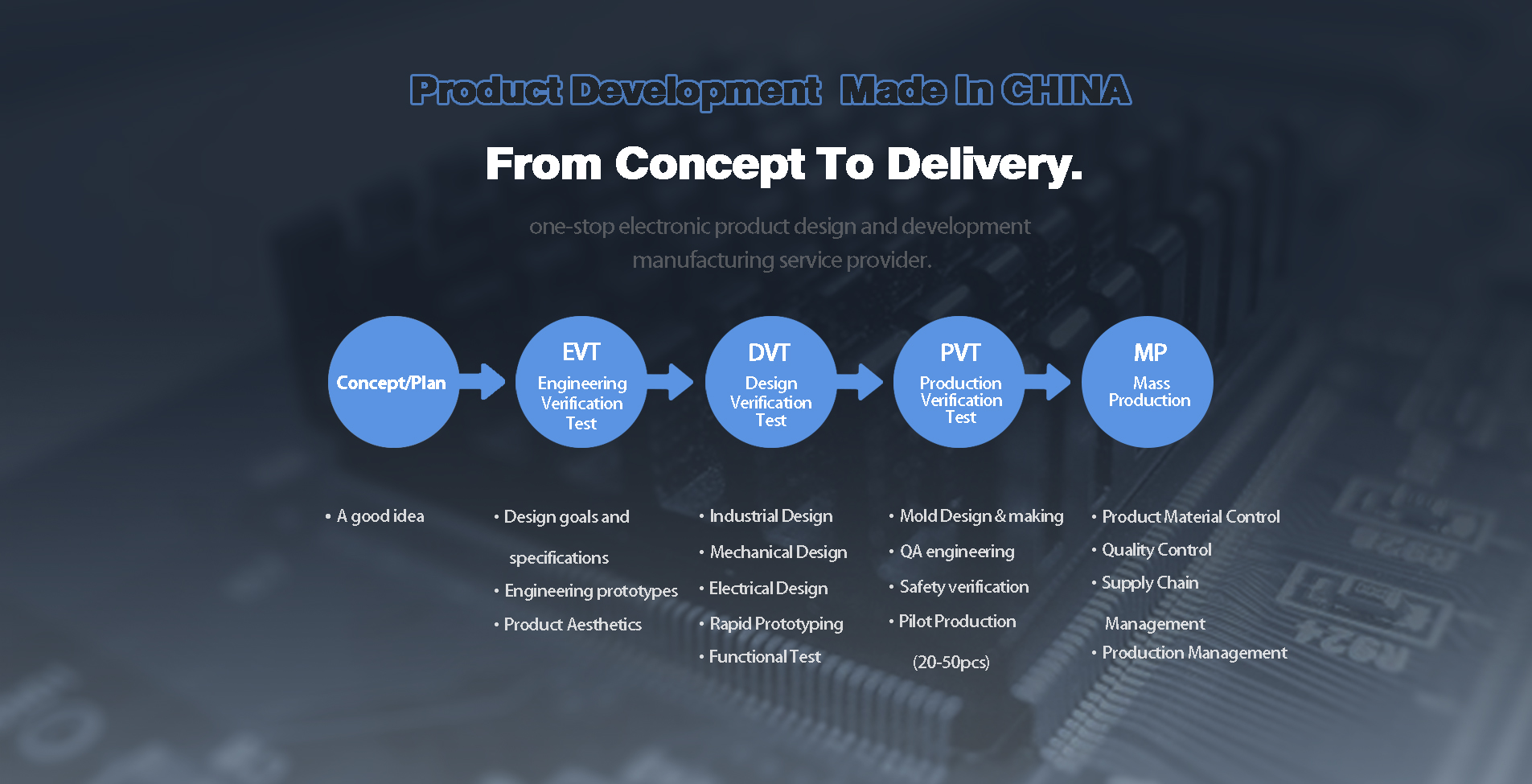

Design Of Welded Structures Where Innovation Meets 2025 From Concept to Delivery

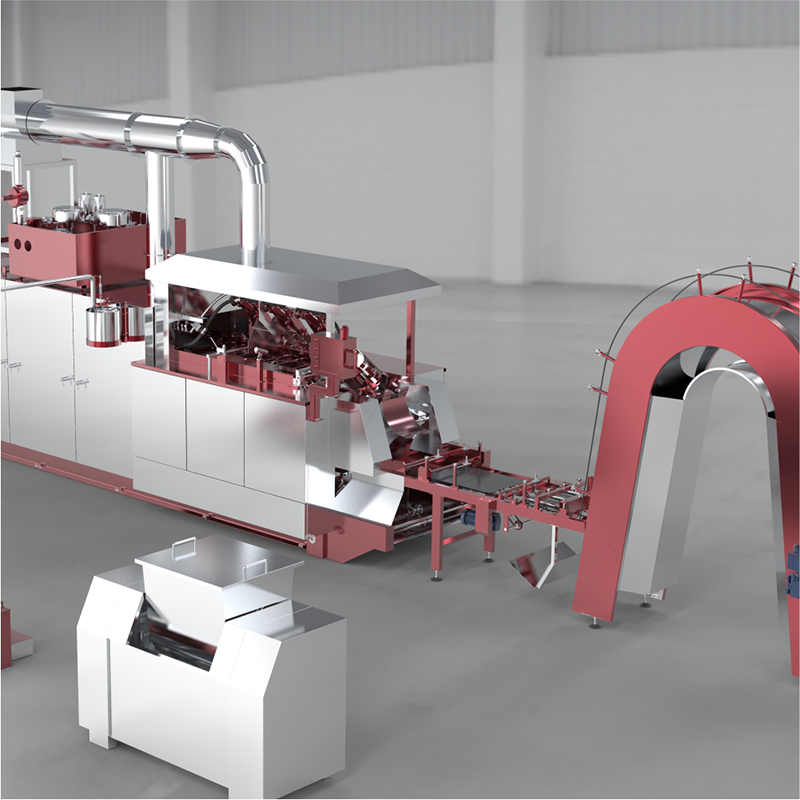

In the ever-evolving landscape of manufacturing, the design of welded structures stands at the forefront, where innovation meets functionality. As we approach 2025, it is essential for global procurement professionals to understand how conceptual advancements can significantly enhance the efficiency and durability of welded products. The integration of cutting-edge technologies, such as advanced CAD systems and 3D modeling, allows for the meticulous planning and execution of projects, ensuring that each component is crafted to meet rigorous safety and performance standards. The journey from concept to delivery involves a commitment to quality at every stage. Collaborating closely with engineering teams and utilizing state-of-the-art materials enables the creation of structures that not only fulfill the specific needs of various industries but also contribute to sustainability goals. As businesses worldwide seek competitive advantages, the ability to rapidly prototype and iterate designs can help them adapt to market demands while maintaining exemplary standards. By focusing on innovations in welding techniques, such as robotic automation and new alloy combinations, organizations can achieve greater precision and strength in their products. These advancements not only optimize production timelines but also reduce waste, making operations more cost-effective. For global buyers, understanding these developments is crucial to anticipate future needs and secure reliable partnerships that will drive success in their respective markets.

Design Of Welded Structures Where Innovation Meets 2025 From Concept to Delivery

| Dimension | Material Type | Application | Welding Technique | Innovation Aspect |

|---|---|---|---|---|

| 1000mm x 500mm | Steel | Structural Beams | MIG Welding | Lightweight Design |

| 1500mm x 300mm | Aluminum | Aerospace Components | TIG Welding | Corrosion Resistance |

| 2000mm x 400mm | Stainless Steel | Food Processing Equipment | Stick Welding | Hygienic Design |

| 1200mm x 800mm | Carbon Steel | Construction Frames | Flux-Cored Welding | Automation Integration |

| 1800mm x 600mm | Titanium | Medical Devices | Electron Beam Welding | Lightweight Structures |

Related Products